Cavagna Group South Africa Proprietary Limited

Cavagna Group South Africa (CGSA), established in 2021, is a proud subsidiary of the globally renowned Cavagna Group. As a trusted leader in the manufacture and supply of high-quality gas control equipment and components, CGSA brings world-class innovation, safety, and reliability to the Southern African energy sector. Our fully established gas metering facility enables us to meet diverse industry needs with precision and efficiency.

We are proud to be a Level 4 contributor to Broad-Based Black Economic Empowerment (B-BBEE), demonstrating our ongoing commitment to inclusive economic growth in South Africa. Additionally, CGSA operates under the internationally recognised ISO 9001:2015 quality management system, ensuring our products and services consistently meet the highest global standards. We have local warehousing of critical stock items.

Mission

“Starting from innovation, wherever gas is the integral part and provides clean energy for everyday life, there will be the technological and productive commitment from Cavagna Group. Comprehensive one-stop solutions for each type of gas, to promote safe and functional utilization in all applications.”

Internal Issues

Internal factors are those within the organization that can influence its ability to achieve its objectives.

Category

• Organizational Structure and Culture

Example of Internal Issues: Hierarchical or flat structure, leadership styles, decision-making processes.

Process efficiency

• Inefficient workflows – The steps within the processes are smooth and not repetitive.

• Outdated technology – The software and systems are always updated and designed for current needs to speed up the tasks and clear

compatibility issues

• Lack of process documentation – There are clear guidelines (written procedures) outlining how the processes should be followed to

ensure consistency and prevent/ minimize errors and confusion among team members.

Resource management

• Staff skill gaps – It is ensured that there are no significant differences between the skills required for a job and the skills currently

possessed by the employees in their roles.

• Inadequate training – The employees are provided with training programs that are sufficient to identify skill gaps by quality training

materials and quality training time targeting the right skills.

• Resource allocation issues – The employees are assigned tasks/ projects based on their skills and availability to avoid project delays

and quality concerns.

Internal communication

• Information silos – It is ensured that different departments do not operate in isolation, readily sharing updates or critical

details, and not creating a knowledge gap.

• Delayed communication – It is ensured that the important news is communicated promptly across departments to avoid

missed deadlines and misaligned efforts.

• Unclear expectations – transparent communication is required to ensure that individuals are aware of what is expected

from their teams. This is to ensure understanding and unduplicated work.

Quality control practices

• Deficiencies in quality checks – Identify and address potential issues quickly and effectively while still maintaining a high

standard of quality in the product or service being checked; essentially, doing a thorough quality check while optimizing the

process to be as productive as possible.

• Inconsistent application of standards – Rules, policies, or expectations are applied firmly across situations or individuals for

fair non-discrepancies where similar cases are treated differently. This is to avoid a lack of equity and the potential for bias.

External Issues

External factors originate outside the organization but can influence its operations and strategic direction.

Economic Factors

• Economic fluctuations – Diversifying income sources, closely managing costs, building emergency funds, adapting to market

changes, maintaining efficient cash flow, identifying potential opportunities during downturns, and staying informed about economic

trends

• Current exchange rate – Regular monitoring of market fluctuations.

• Raw material cost – Carefully tracking the raw material usage, negotiating with suppliers, diversifying the sourcing options,

optimizing inventory levels, implementing lean manufacturing practices to reduce waste, monitoring price fluctuations, and

considering alternative materials or production processes when possible.

Market trends

• Customer demands – Prioritizing active listening, demonstrating empathy, clearly communicating with customers, managing

expectations, staying calm, and being open to feedback, while also assessing their needs and finding solutions to address their

concerns thoughtfully; essentially, strive to create a customer-centric culture where you prioritize understanding and meeting

customer needs. Emerging technologies – New or recently introduced technologies that have the potential to change society and the

economy

• Emerging technology – actively staying informed about new advancements, assessing their potential impact on your field, evaluating

their feasibility for your business, considering pilot projects to test them, and fostering a culture of continuous learning within your

organization to adapt and potentially leverage new technologies as they arise.

• Competitor activity – Conducting a thorough competitor analysis to understand their strengths and weaknesses, identifying

market gaps, and then leveraging our unique selling proposition (USP) to differentiate our product or service, while actively

monitoring their actions to adapt our strategies accordingly; key steps include identifying y competitors, analyzing their

products and marketing strategies, and developing a strategy to highlight our unique advantages in the market.

Social environmental factors

• Sustainability concerns – conducting a sustainability assessment, reducing waste, switching to renewable energy, optimizing

resource usage, engaging with your supply chain to ensure ethical practices, promoting transparency, setting clear

sustainability goals, and actively monitoring progress while incorporating environmental, social, and economic factors into

decision-making across your operations.

• Public perception – focusing on being transparent and accountable, actively engaging with your audience, listening to

feedback, addressing concerns promptly, communicating clearly and consistently, and taking proactive steps to build a

positive image by aligning your actions with your stated values.

Legal and regulatory changes

• New laws – The businesses will establish a proactive monitoring system to stay informed about upcoming legislation, consult with legal

experts to assess the impact of new laws on their operations, develop implementation plans to adapt to changes, and regularly review

compliance procedures to ensure ongoing adherence; this includes actively engaging with industry associations and government

agencies to gain insights into potential regulatory shifts.

• Compliance requirements – continuously monitor relevant regulations, conduct regular risk assessments, develop clear compliance

policies, provide comprehensive employee training, and implement internal audit processes to identify and address potential

issues; actively communicating updates and changes to staff is also crucial.

• Standards updates – Establishing a dedicated compliance team to actively monitor relevant updates, conducting regular internal

audits to assess compliance gaps, implementing necessary changes to policies and procedures, providing ongoing employee training

on new regulations, and leveraging technology to automate compliance tracking and reporting; this ensures proactive adaptation to

evolving legal landscapes and minimizes potential risks.

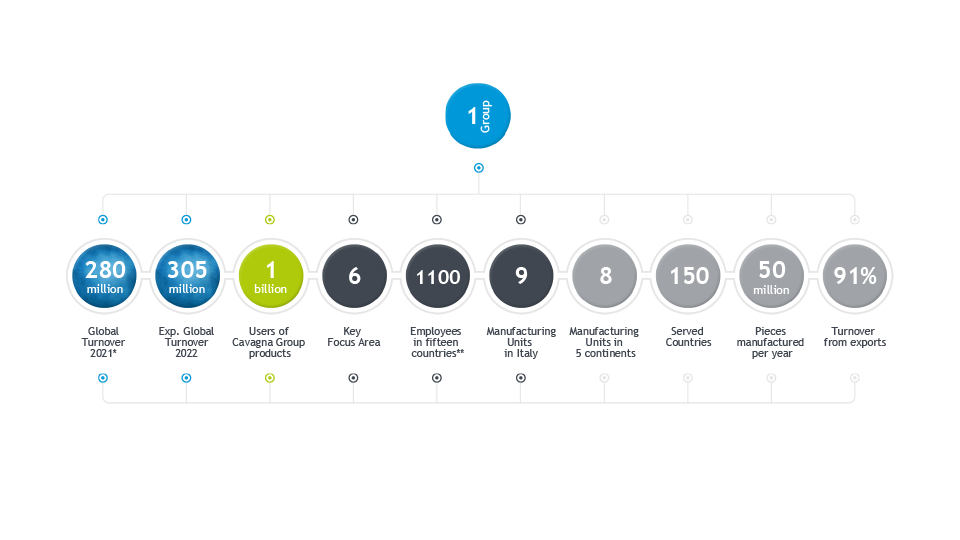

Selected key figures

*Group Total Sales (Partner Company revenues are not included)

**This number does not consider: REPCo, CGE Light Assembly, Mesura Nirmal, Congrif

History

1949

Paolo Cavagna founded the Cavagna Group

1964

The Group founded O.ME.CA

1981

Cavagna Group created CORI ENGINEERING

1984

Cavagna founded CAVIMATIC merged in 2019 with CAVAGNA GROUP ENGINEERING, founded in 2009

1991

IN.CA Srl of Calvagese became Enne.Pi Srl, dedicated to the large-scale mass production of LPG valves

1991

The Group took over PERGOLA

1996

The Cavagna Group founded Cavagna North America Inc.

1997

The Cavagna Group took over its historical British competitor Calor gas Engineering Ltd and founded CAVAGNA GROUP UK Ltd

1999

The Cavagna Group took over Kosan Teknova in denmark from which KOSAN INTERNATIONAL was born in 2000 and KOSAN PORTUGAL in 2003

2003

The Group purchase of quotas in bangkok with the thai company svmetals ltd which later became CAVAGNA GROUP ASIA

2006

Cavagna Group extended its activities in the Far East by setting up its own manufacturing plant for LPG and natural gas regulators in Zhongshan China

2009

The Group founded the Turkey Distribution

2009

The Cavagna Group signed a partnership agreement with Mesura SA, a French company devoted to natural gas regulators and metering stations, completely acquired in 2012

2010

The Group took over CEMCO in Chile, a former competitor in the field of LPG valves and pressure regulators

2010

Cavagna Group founded CAVAGNA GROUP VIETNAM

2013

The Group strengthened its international presence in Asia through a joint venture in Mumbai, India. MESURA NIRMAL GAS CONTROL is specialized in the manufacture of Natural Gas regulators for residential, commercial and Industrial use.

2016

Cavagna Group founded Brasil Distribution

2018

The Cavagna Group expanded its product range, so that it now includes gas meters alongside its regulators with the foundation of Mesura Metering srl

2021

Cavagna Group and its partner Nirmal joined their efforts to acquire REPCo, a company based in Milano, dedicated to Process Design House whose services cover the design, supply and start-up site support of packaged Oil & gas related systems

2021

Cavagna Group opens the subsidiary CAVAGNA GROUP SOUTH AFRICA, located in Johannesburg

2023

To expand its presence on the African continent, CAVAGNA GROUP WEST AFRICA , based in Abidjan, Côte d'Ivoire, was established in 2023. The company will cover the ECOWAS region and other West African countries

Still Have Questions? Just Ask

We will be happy to answer all your questions

and support you with our experience.